Barrier Coating with Epoxy

Barrier coating with epoxy builds an epoxy coating that provides an effective moisture barrier and a smooth base for final finishing.

Apply a minimum of two coats of WEST SYSTEM epoxy for an effective moisture barrier. Apply three coats if sanding is to be done. Moisture protection will increase with additional coats, up to six coats or about a 20-mil thickness. Additives or pigments should not be added to the first coat. Mixing thinners with WEST SYSTEM epoxy is not recommended.

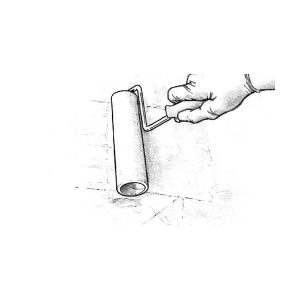

Roll lightly and randomly over a small area, spreading the epoxy into a thin, even film.

Disposable, thin urethane foam rollers, such as WEST SYSTEM 800 Roller Covers, allow you greater control over film thickness. They are less likely to cause the epoxy to exotherm and leave less stipple than thicker roller covers. Cut the covers into narrower widths to reach difficult areas or for long narrow surfaces like stringers.

Complete all fairing and cloth applications before beginning the final coating. Allow the temperature of porous surfaces to stabilize before coating. Otherwise, as the material warms up, the air within the porous material may expand and pass from the material (out-gassing) through the coating and leave bubbles in the cured coating.

- Prepare the surface for epoxy bonding.

- Mix only as much epoxy resin/hardener as you can apply during the open time of the mixture. Pour the mixture into a roller pan as soon as it is mixed thoroughly.

- Load the roller with a moderate amount of the epoxy mixture. Roll the excess out on the ramp part of the roller pan to get a uniform coating on the roller.

- Roll epoxy lightly and randomly over an area of approximately 2 ft x 2 ft to transfer the epoxy evenly over the area.

- As the roller dries out, increase pressure enough to spread the epoxy into a thin even film. Increase the coverage area if necessary to spread the film more thinly and evenly. The thinner the film, the easier it is to keep it even and avoid runs or sags in each coat.

Tip-off the coating by dragging a foam roller brush lightly over the fresh epoxy.

- Finish the area with long, light, even strokes to reduce roller marks. Overlap the previously epoxy-coated area to blend both areas together.

- Coat as many of these small working areas as you can with each batch of epoxy. If a batch begins to thicken before it can be applied, discard it and mix a fresh, smaller batch.

- Tip-off the epoxy coating by dragging a foam roller brush lightly over the fresh epoxy in long, even, overlapping strokes after each batch is applied. Use enough pressure to smooth the stipple, but not enough to remove any of the epoxy coating. Alternate the direction in which each epoxy coat is tipped off, 1st coat vertical, 2nd coat horizontal, 3rd coat vertical, etc. A WEST SYSTEM 800 Roller Cover can be cut into segments to make a tipping brush.

Recoating

Apply second and subsequent coats of epoxy following the same procedures. Make sure the previous coat has cured firmly enough to support the weight of the next coat. To avoid sanding between coats, apply all of the coats in the same day. After the final epoxy coat has cured overnight, wash and sand it to prepare for the final finish.

Learn more about barrier coating

Read about how WEST SYSTEM Technical Advisor Bruce Niederer used an epoxy barrier coat to prevent gelcoat blisters on his 1981 Pearson Flyer, Triple Threat at Epoxyworks.com in his article, Triple Threat, 38 years old and counting.