There are two types of structural bonding with epoxy.

Two-step bonding is the preferred method for most situations because it promotes maximum epoxy penetration into the bonding surface and prevents epoxy-starved joints. Single-step bonding can be used when joints have minimal loads and excess absorption into porous surfaces is not a problem. In both cases, epoxy bonds best when it is worked into the surface with a roller or brush.

Before mixing epoxy, check all parts to be bonded for proper fit and surface preparation, gather all the clamps and tools necessary for the operation, and cover any areas that need protection from spills.

Primary/Secondary Bonding with Epoxy

Primary bonding with epoxy relies on the chemical linking of adhesive layers such as the wet lay-up of fiberglass laminate in a mold. All the layers of epoxy cure together in a single fused layer. Epoxy applied over partially cured epoxy will chemically link with it and is a primary bond. The ability to chemically link diminishes as the epoxy cures and becomes a secondary bond.

Secondary bonding relies on the mechanical linking of an adhesive to a material or cured epoxy surface. The adhesive must “key” into pores or scratches in the surface-a microscopic version of a dovetail joint. Proper surface preparation provides a texture that will help lock the cured epoxy to the surface.

Two-Step Epoxy Bonding

- Wet-out epoxy bonding surfaces-Apply a neat epoxy resin/hardener mixture (without fillers) to the surfaces to be joined. Wet out small or tight areas with a disposable brush. Wet out larger areas with a foam roller or by spreading the resin/hardener mixture evenly over the surface with a plastic spreader. You may proceed with step two immediately or any time before the wet-out epoxy coat reaches the final cure stage.

- Apply thickened epoxy to one bonding surface. Modify the epoxy resin/hardener mixture by stirring in the appropriate filler until it becomes thick enough to bridge any gaps between the mating surfaces and to prevent “resin-starved” joints. Apply enough of the mixture to one of the surfaces, so that a small amount of epoxy will squeeze out when the surfaces are joined together with a force equivalent to a firm hand grip. Thickened epoxy can be applied immediately over the wet-out surface or any time before the wet-out reaches its final cure. For most small epoxy bonding operations, add the filler to the resin/hardener mixture remaining in the batch that was used for the wet-out. Mix enough epoxy resin/hardener for both steps. Add the filler quickly after the surface is wet out and allow for a shorter working life of the epoxy mixture.

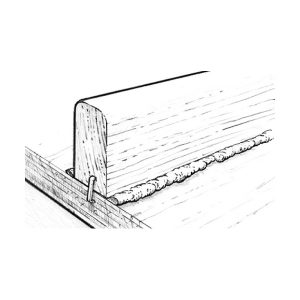

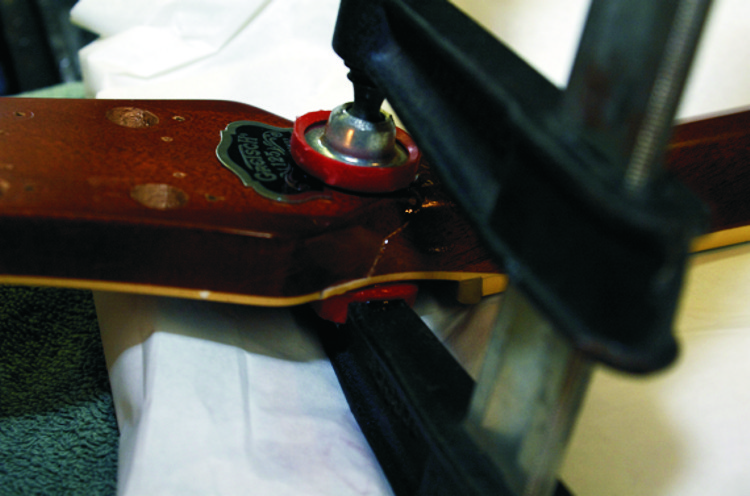

- Clamp components. Attach clamps as necessary to hold the components in place. Use just enough clamping pressure to squeeze a small amount of the epoxy mixture from the joint, indicating that the epoxy is making good contact with both mating surfaces. Avoid using too much clamping pressure, which can squeeze all of the epoxy mixture out of the joint.

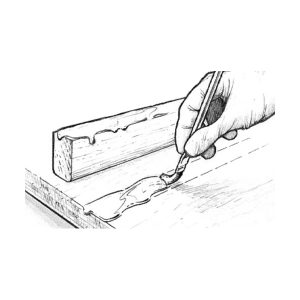

- Remove or shape excess epoxy that squeezes out of the joint as soon as the joint is secured with clamps. A wooden mixing stick with one end sanded to a chisel edge is an ideal tool for removing the excess epoxy.

Single-Step Epoxy Bonding

Single-step bonding is applying the thickened epoxy directly to both bonding surfaces without first wetting out the surfaces with neat epoxy resin/hardener. We recommend that you thicken the epoxy no more than is necessary to bridge gaps in the joint (the thinner the mixture, the more it can penetrate the surface) and that you do not use this method for highly-loaded joints or for bonding end grain or other porous surfaces.

Laminating with Epoxy

The term “laminating” refers to the process of bonding numbers of relatively thin layers, like plywood, veneers, fabrics or core material to create a composite. A composite may be any number of layers of the same material or combinations of different materials. Methods of epoxy application and clamping will differ depending on what you are laminating.

Because of large surface areas and limitations of wet lay-up time, roller application is the most common method for applying epoxy. A faster method for large surfaces is to simply pour the epoxy resin/hardener mixture onto the middle of the panel and spread the mixture evenly over the surface with a plastic spreader. Apply thickened epoxy mixtures with an 809 Notched Spreader. Using staples or screws is the most common method of clamping when you laminate a solid material to a solid substrate. An even distribution of weights will work when you are laminating a solid material to a base that will not hold staples or screws, such as a foam or honeycomb core material. Vacuum bagging is the ideal clamping method for laminating a wide range of materials. Through the use of a vacuum pump and plastic sheeting, the atmosphere is used to apply perfectly even clamping pressure over all areas of a panel regardless of the size, shape or number of layers.

Clamping Epoxied Components

With epoxy, any method of clamping is suitable as long as the parts to be joined are held so that movement will not occur. Common methods include spring clamps, “C” clamps and adjustable bar clamps, heavy rubber bands cut from inner tubes, nylon-reinforced packaging tape, applying weights, and vacuum bagging. When placing clamps near epoxy-covered areas, cover clamp pads with duct tape, or use polyethylene sheeting or release fabric under the clamps so they don’t inadvertently bond to the epoxied surface. Staples, nails or drywall screws are often used where conventional clamps will not work. Any fasteners left in should be of a non-corroding alloy such as bronze. In some cases, the thickened epoxy or gravity will hold parts in position without clamps.

Pre-coating porous surfaces with neat (unthickened) epoxy before applying a thickened epoxy adhesive or fairing compound improves adhesion. Neat epoxy penetrates and “keys” into surface pores and end-grain better than thicker epoxy.

Bonding with Epoxy Fillets

A fillet (fil’it) is a cove-shaped application of thickened epoxy that bridges an inside corner joint. It is excellent for bonding parts because it increases the surface area of the bond and serves as a structural brace. All joints that will be covered with fiberglass cloth will require a fillet to support the cloth at the inside corner of the joint.

Joint strength is the ability of a joint to adequately transfer a load from one part to another, and depends on the combined effects of three factors:

- Glue Strength—Careful metering and thorough mixing will ensure the epoxy mixture cures to full strength.

- Adhesion—For the best adhesion and load transfer, the epoxy joint’s bonding surfaces must be properly prepared.

- Joint Area—The epoxy bonding area of the joint must be adequate for the load on the joint and the materials being joined. Increased overlap, scarf joints, filets, and reinforcing fibers can be used to increase the joint bonding area.

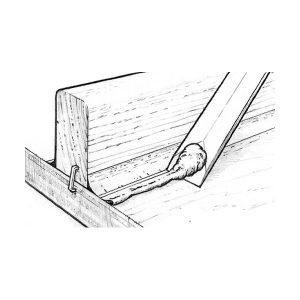

The procedure for bonding with epoxy fillets is the same as normal bonding except that instead of removing the squeezed-out thickened epoxy after the components are clamped in position, you shape it into a fillet. For larger epoxy fillets, add the thickened mixture to the joint as soon as the bonding operation is complete before the epoxy bonding mixture is fully cured, or any time after the final cure and sanding of exposed epoxy in the fillet area.

- Bond parts as described in Bonding.

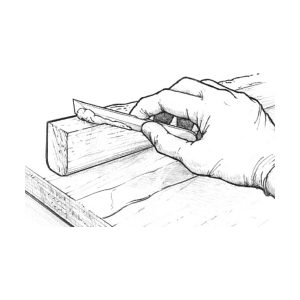

- Shape and smooth the squeezed-out thick epoxy into a fillet by drawing a rounded filleting tool (mixing stick) along the joint, dragging excess material ahead of the tool and leaving a smooth cove-shaped fillet bordered on each side by a clean margin. Some excess filleting material will remain outside of the margin. Use the excess material to re-fill any voids. Smooth the fillet until you are satisfied with its appearance. A mixing stick will leave a fillet with about a 3/8″ radius. For larger fillets, an 808 Plastic Squeegee, cut to shape or bent to the desired radius, works well. Apply additional thickened epoxy to fill voids or make larger fillets. Apply the mixture along the joint line with the rounded mixing stick, using enough epoxy mixture to create the desired size of the fillet. For longer or multiple fillets, empty caulking gun cartridges or disposable cake decorating bags can be used. Cut the plastic tip to lay a bead of thickened epoxy large enough for the desired fillet size. Heavy-duty, sealable food storage bags with one corner cut off may also be used.

- Clean up the remaining excess material outside of the margin by using a sharpened mixing stick or a putty knife. Fiberglass cloth or tape may be applied over the fillet area before the fillet has been cured (or after the fillet is cured and sanded).

- Sand smooth with 80-grit sandpaper after the epoxy fillet has fully cured. Wipe the surface clean of any dust and apply several coats of resin/hardener over the entire fillet area before final finishing.

Learn more about epoxy fillets

Read Tom Pawlak’s comprehensive and informative article “Bonding with Fillets” in Epoxyworks 44.