-

Description -

Quick Links -

Resources -

Relevant Videos -

Faq -

Related Products -

Where To Buy

PROJECT USES:

- Marine

- Boat Repair

- Adhesion

- Fabrication

- Molding

- Furniture

- Casting

CURE TIME:

Working time (thin film) is based on which hardener you choose at 72°F (22°C):

- 205 Fast Hardener®: 60 to 70 minutes

- 206 Slow Hardener®: 90-110 minutes

- 207 Special Clear Hardener®: 100-200 minutes

- 209 Extra Slow Hardener®: 3-4 hours

CURE TEMP:

Based on which hardener you choose, solid-state curing happens in a wide range of durations at 72°F (22°C). Minimum recommended temperatures:

- 205 Fast Hardener®: 40°F (4°C)

- 206 Slow Hardener®: 60°F (16°C)

- 207 Special Clear Hardener: 60°F (16°C)

- 209 Extra Slow Hardener®: 70˚F (21˚C)

PRODUCT SIZES:

- 105-A: 1 quart

- 105-B: .98 gallon

- 105-C: 4.35 gallon

- 105-E: 52.03 gallon

105 Epoxy Resin Facts

QUICK LINKS Helpful Tips, Safety Guidelines, Manuals, and More:

Helpful Tips, Safety Guidelines, Manuals, and More:

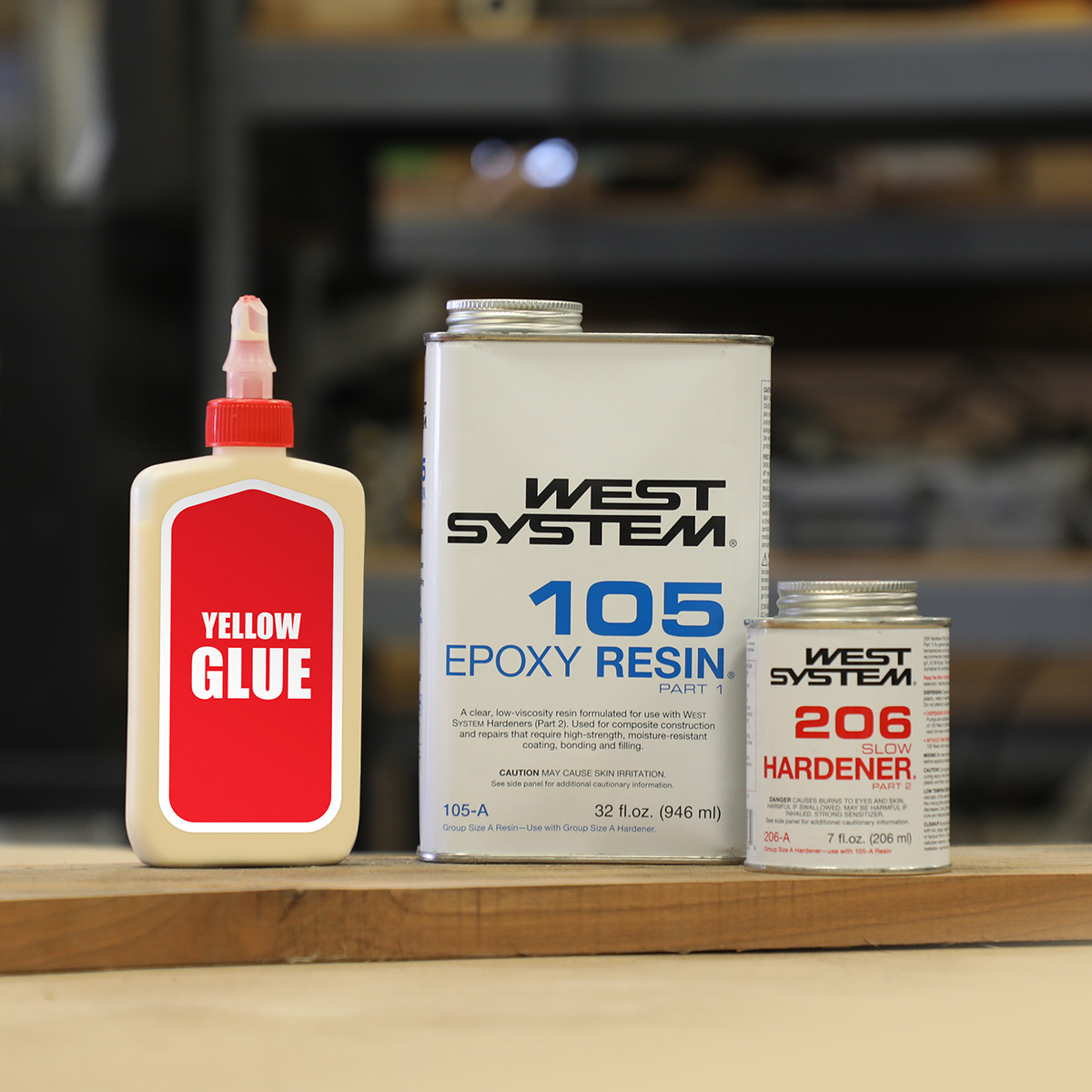

YELLOW GLUE VS EPOXY

When should you use yellow glue (also called wood glue or carpenter’s glue) and when should you use WEST SYSTEM® Epoxy? This is common question epoxy users ask, especially when trying to choose the best adhesive for their woodworking projects. Let’s look at when one is a better choice than the other, and why.