-

Description -

Quick Links -

Resources -

Relevant Videos -

Faq -

Related Products -

Where To Buy

PROJECT USES:

- Marine

- Boat Repair

- Bonding

- Fabrication

- Barrier Coating

CURE TIME:

- Pot life (100 grams cupful):

- At 72°F (22°C): 9 to 12 minutes

- Working time (thin film):

- At 72°F (22°C): 60 to 70 minutes

- Solid state:

- At 72°F (22°C): 6 to 8 hours

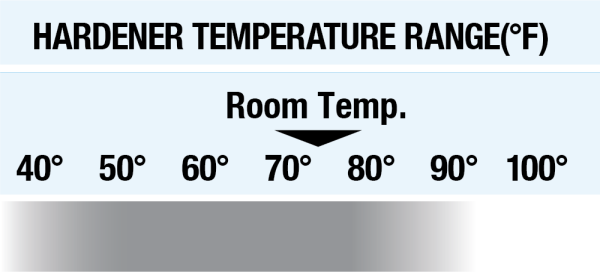

CURE TEMP:

- Minimum: At 40°F (4°C)

PRODUCT SIZES:

- 205-A: 0.44 pint

- 205-B: 0.86 quart

- 205-C: .94 gallon

- 205-E: 11.31 gallon

205 FAST HARDENER Facts

QUICK LINKS Helpful Tips, Safety Guidelines, Manuals, and More:

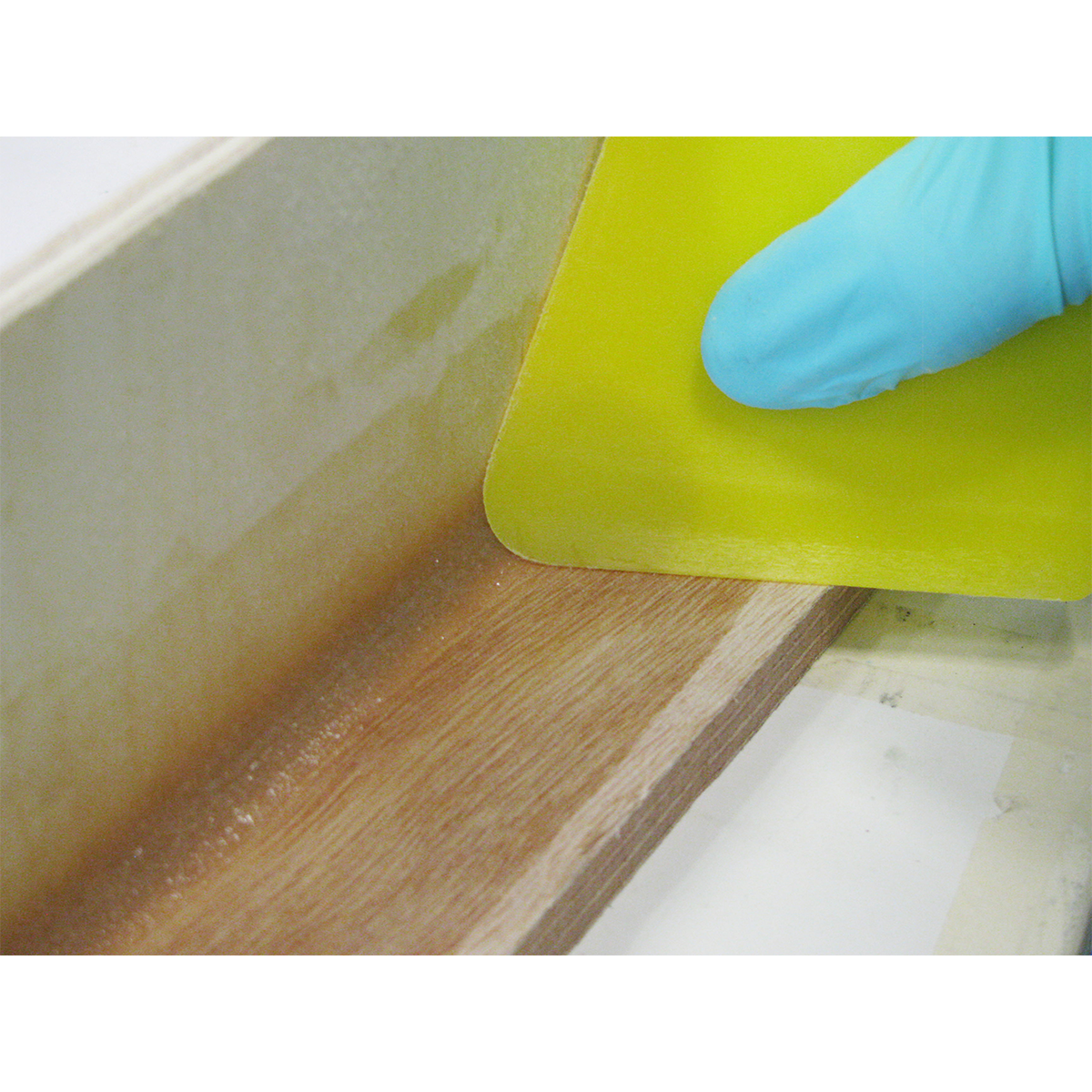

BONDING & CLAMPING

There are two types of structural bonding with epoxy. Two-step bonding is the preferred method for most situations because it promotes maximum epoxy penetration into the bonding surface and prevents epoxy-starved joints. Single-step bonding can be used when joints have minimal loads and excess absorption into porous surfaces is not a problem.