Applying fiberglass or tape to surfaces provides reinforcement, abrasion-resistance, and prevents grain checking.

If you plan to apply fiberglass cloth, this is typically done after you’ve finished fairing and shaping, and before applying your final coat. Fiberglass cloth can be applied in multiple layers (laminated) and in combination with other materials to build composite parts.

There are two application methods – the “dry” method, and the “wet” method. The dry method refers to applying the cloth over a dry surface, whereas the wet method refers to applying the cloth to an epoxy-coated surface (often after the wet-out coat becomes tacky, which helps it cling to vertical or overhead surfaces). Since the wet method makes it more difficult to position the cloth, the dry method is often easier to execute (especially with thinner cloth).

Dry Method of Applying Fiberglass Cloth or Tape

- Prepare the surface as you would for epoxy bonding.

- Position the fiberglass cloth over the surface and cut it several inches larger on all sides. If the surface area you are covering is larger than the cloth size, allow multiple pieces to overlap by approximately two inches. On sloped or vertical surfaces, hold the cloth in place with masking or duct tape, or with staples.

- Mix a small quantity of epoxy (three or four pumps each of resin and hardener).

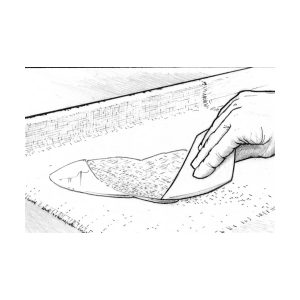

- Pour a small pool of epoxy resin/hardener near the center of the cloth.

- Spread the epoxy over the fiberglass cloth surface with a plastic spreader, working the epoxy gently from the pool into the dry areas. Use a foam roller or brush to wet out fabric on vertical surfaces. Properly wet-out fabric is transparent. White areas indicate dry fabric. If you are applying fiberglass cloth over a porous surface, be sure to leave enough epoxy to be absorbed by both the cloth and the surface below it. Try to limit the amount of squeegeeing you do while applying fiberglass cloth. The more you “work” the wet surface, the more minute air bubbles are placed in suspension in the epoxy. This is especially important if you plan to use a clear finish. You may use a roller or brush to apply epoxy to horizontal as well as vertical surfaces. Smooth wrinkles and position the cloth as you work your way to the edges. Check for dry areas (especially over porous surfaces) and re-wet them as necessary before proceeding to the next step. If you have to cut a pleat or notch in the fiberglass cloth to lay it flat on a compound curve or corner, make the cut with a pair of sharp scissors and overlap the edges for now.

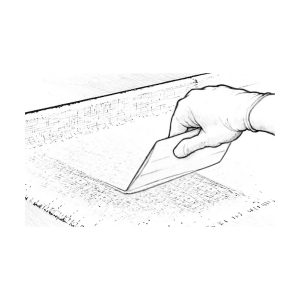

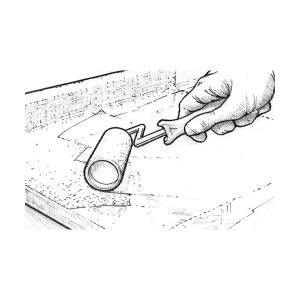

- Use a plastic spreader to squeegee away excess epoxy before the first batch begins to gel. Slowly drag the squeegee over the fiberglass fabric at a low, almost flat, angle, using even-pressured, overlapping strokes. Use enough pressure to remove excess epoxy that would allow the cloth to float off the surface, but not enough pressure to create dry spots. Excess epoxy appears as a shiny area, while a properly wet-out surface appears evenly transparent, with a smooth, cloth texture. Later coats of epoxy will fill the weave of the cloth.

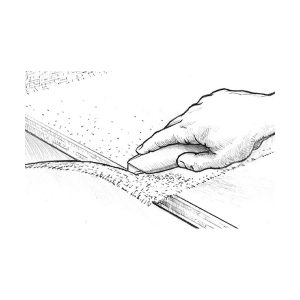

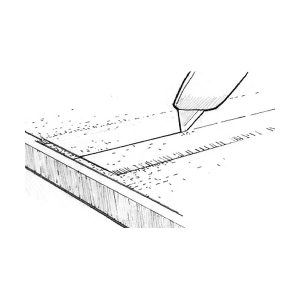

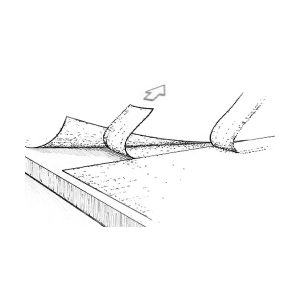

- Trim the excess and overlapped cloth after the epoxy has reached its initial cure. The cloth will cut easily with a sharp utility knife. Trim overlapped cloth, if desired, as follows:

- Place a metal straightedge on top of and midway between the two overlapped edges. b.) Cut through both layers of cloth with a sharp utility knife. c.) Remove the top-most trimming and then lift the opposite cut edge to remove the overlapped trimming. d.) Re-wet the underside of the raised edge with epoxy and smooth it into place. The result should be a near-perfect butt joint, eliminating double cloth thickness. A lapped joint is stronger than a butt joint, so if appearance is not important, you may want to leave the overlap and fair in the unevenness after coating.

- Coat the surface with epoxy to fill the weave before the wet-out reaches its final cure stage.

Follow the procedures for final surface preparation. It will take two or three coats of epoxy to completely fill the weave of the cloth and to allow for a final sanding that will not affect the cloth.

Wet Method of Applying Fiberglass Cloth or Tape

An alternative method of applying fiberglass cloth is to place the fabric or tape directly on a surface that has already been coated with wet epoxy. As mentioned, this is not the preferred method, especially with large pieces of cloth, because of the difficulty removing wrinkles or adjusting the position of the cloth as it is being wet out. However, you may come across situations when this method may be useful or necessary.

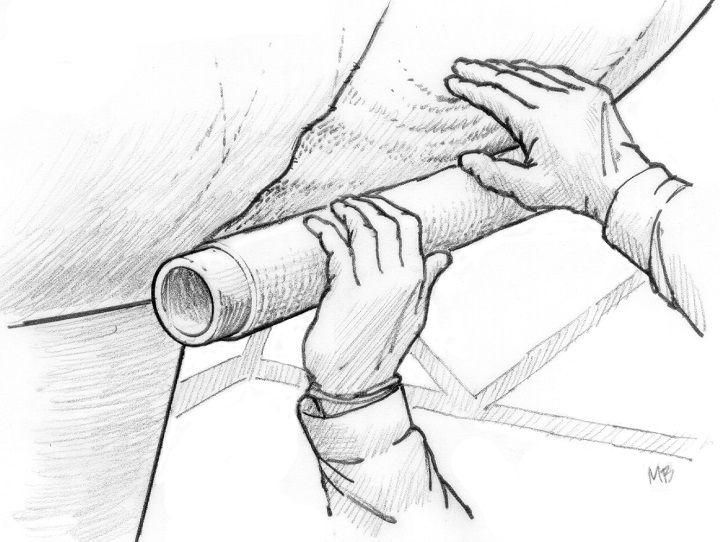

- Prepare the surface for epoxy bonding. Pre-fit and trim the cloth to size. Roll the cloth neatly so that it may be conveniently rolled back into position later.

- Roll a heavy coat of epoxy on the surface.

- Unroll the glass cloth over the wet epoxy and position it. Surface tension should hold the cloth in position. If you are applying the cloth vertically or overhead, you may want to thicken the epoxy slightly with filler, then wait until it becomes sticky. Work out wrinkles by lifting the edge of the cloth and smoothing from the center with your gloved hand or a squeegee.

- Apply a second coat of epoxy with a foam roller. Apply enough epoxy to thoroughly wet out the cloth.

- Remove the excess epoxy with a spreader, using long overlapping strokes. The cloth should appear consistently transparent with a smooth cloth texture.

- Trim the excess and overlapped cloth after the epoxy has reached its initial cure. The cloth will cut easily with a sharp utility knife. Trim overlapped cloth, if desired, as follows:

a.) Place a metal straightedge on top of and midway between the two overlapped edges. b.) Cut through both layers of cloth with a sharp utility knife. c.) Remove the top-most trimming and then lift the opposite cut edge to remove the overlapped trimming. d.) Re-wet the underside of the raised edge with epoxy and smooth into place. The result should be a near-perfect butt joint, eliminating double cloth thickness. A lapped joint is stronger than a butt joint, so if appearance is not important, you may want to leave the overlap and fair in the unevenness after coating. - Coat the surface with more epoxy to fill the weave before the wet-out reaches its final cure stage.

Any remaining irregularities or transitions between cloth and substrate can be faired by using an epoxy/filler fairing compound if the surface is to be painted. Any additional fairing done after the final epoxy coating should receive several additional coats over the faired area.

Note: A third alternative for more experienced users is a variation of both methods. Apply the fabric after a wet-out coat of epoxy has reached an initial cure. Follow the first three steps of the Wet Method, but wait until the epoxy cures dry to the touch before positioning the fabric and continuing with Step 3 of the Dry Method. Apply the fabric before the first coat reaches its final cure phase.

Clear Epoxy Finishes Over Wood (bright finishes)

An alternative wet out method for bright finishes is to lay the epoxy onto the fabric with a short-bristled brush. Dip the brush in the epoxy and lay the epoxy on the surface with light even strokes. Don’t force the epoxy into the cloth, which may trap air in the fabric and show through the clear finish. Apply enough epoxy to saturate the fabric and the wood below. After several minutes, lay on additional epoxy to dry (white) areas. If epoxy appears milky due to high humidity or over-working, warm the surface by passing a heat gun or hair dryer over the surface. Use low heat to avoid out-gassing. Be sure to use 207 Special Clear Hardener for clear finishes.

Repairing a Fiberglass Tub or Shower?

Find out how to use WEST SYSTEM Epoxy for Fiberglass Tub and Shower Repair at Epoxyworks.com.