-

Description -

Quick Links -

Resources -

Relevant Videos -

Faq -

Related Products -

Where To Buy

PROJECT USES:

- Marine

- Boat Repair

- Clear Casting

- Coating

- Laminating

- Clear Coating Wood Surfaces

CURE TIME:

- Pot life (100 grams cupful):

- At 72°F (22°C): 20 to 26 minutes

- Working time (thin film):

- At 72°F (22°C): 100 to 120 minutes

- Solid state:

- At 72°F (22°C): 10 to 15 hours

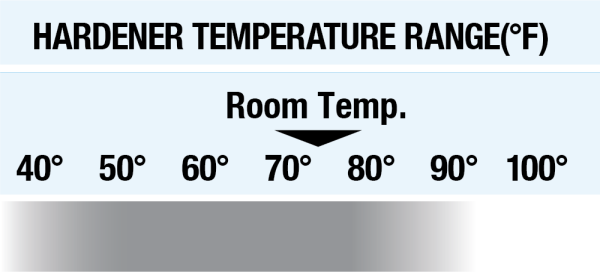

CURE TEMP:

- Minimum: At 60°F (16°C)

PRODUCT SIZES:

- 207-SA: 0.66 pint

- 207-SB: 0.33 gallon

- 207-SC 1.45 gallon

- 207-SE: 17.34 gallon

207 SPECIAL CLEAR HARDENER Facts

QUICK LINKS Helpful Tips, Safety Guidelines, Manuals, and More:

CLEAR COATING WITH 207 SPECIAL CLEAR HARDENER

Not that long ago, clear coating with epoxy meant that you were finishing a natural wood canoe or kayak, or the teak toe rails on your boat. Today, WEST SYSTEM 105 Resin and 207 Special Clear Hardener is used for clear coating in many different ways. Regardless of the project, there are some basic techniques to follow when epoxy coating and a few pitfalls to avoid