-

Description -

Quick Links -

Resources -

Relevant Videos -

Faq -

Related Products -

Where To Buy

PROJECT USES:

- Marine

- Boat Repair

- Bonding

- Fabrication

- Barrier Coating

CURE TIME:

- Pot life (100 grams cupful):

- At 72°F (22°C): 40 to 50 minutes

- Working time (thin film):

- At 72°F (22°C): 3 to 4 hours

- Solid state:

- At 72°F (22°C): 20 to 24 hours

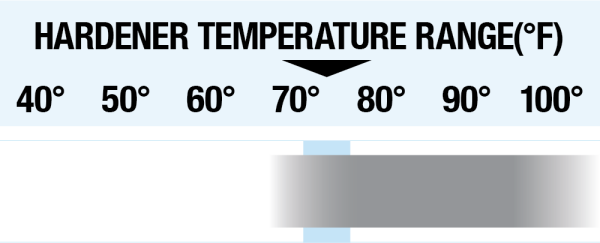

CURE TEMP:

PRODUCT SIZES:

- 209-SA: 0.66 pint

- 209-SB: 0.33 gallon

- 209-SC: 1.45 gallon

- 209-SE: 17.34 gallon

209 EXTRA SLOW HARDENER Facts

QUICK LINKS Helpful Tips, Safety Guidelines, Manuals, and More:

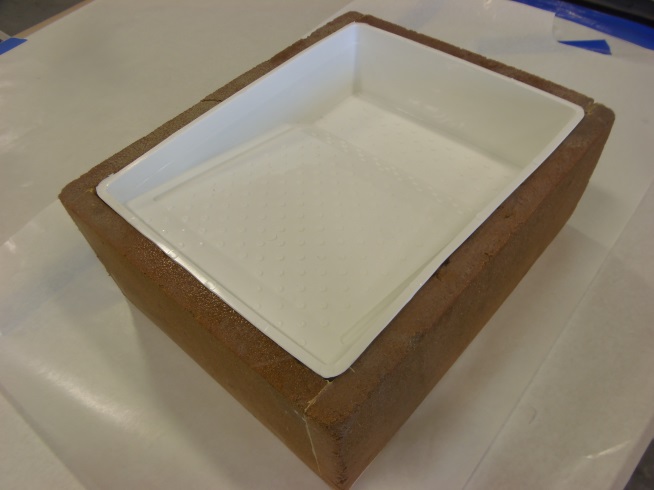

UNCONTROLLED CURE

Controlling exotherm (the heat released by the chemical reaction between resin and hardener that cures epoxy) is very important, especially when mixing larger batches of resin and hardener. If not controlled, epoxy’s exothermic reaction can be dangerous.