A complete starter vacuum bagging kit for room temperature repairs and small laminating projects up to 13 sq ft. Some item specifications may vary.

885 Vacuum Bagging Kit

Some item specifications may vary –see price list.

885 Vacuum Bagging Kit includes all items below.

Kit includes:

- Venturi Vacuum Generator with Silencer*

- 3 Vacuum Cups, 20′ of ¼” Vacuum Tubing*

- 0-30Hg Vacuum Gauge*

- 2 Junction “T” barbs

- 15 sq ft Release Fabric

- 15 sq ft Breather Fabric

- 15 sq ft Vacuum Bag Film

- 25′ Vacuum Bag Sealant

- Complete, Illustrated Instructions

*Indicates that item is available as a replacement part.

2—Junction “T” barbs

T’s are used to connect tubing lines and cups. May be used to place a resin trap just ahead of the Venturi intake.

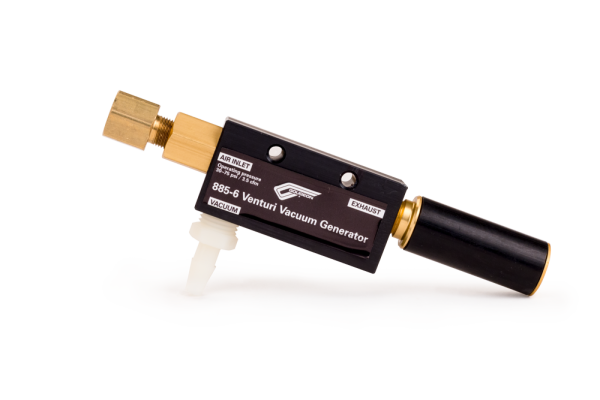

1—Venturi Vacuum Generator with Silencer*

The Vacuum Generator develops over 20 inches Hg (mercury) of vacuum (10 psi of clamping pressure) at .4 SCFM and is designed to run off of conventional shop air compressors that continuously deliver at least 65 psi at 3.5 SCFM. Some item specifications may vary. (A ¼” NPT male air fitting is required to connect to your air compressor.)

3—Vacuum Cups*

Cups are placed over a ½” “X” cut in the vacuum bag film and provide a port through the bag for the vacuum gauge or the vacuum tubing. 20 ft—885-4 ¼” I.D Vacuum Tubing. Cut tubing to the appropriate length, to connect the vacuum cups to the generator and make a resin trap.

1—Vacuum Gauge*

The Gauge screws into a vacuum cup and is placed over a ½” “X” cut in the vacuum bag film. Vacuum measurement is expressed in inches of mercury (0-30 Hg). Each increase of 1 inch of mercury (a single increment on the gauge) indicates an addition of about seventy pounds of pressure per sq ft (.48 psi) at sea level.

15 SQ FT—879 RELEASE FABRIC

Release fabric peels cleanly away from the cured epoxy. Cut it to fit an area larger than the repair area or saturated laminate layup.

15 SQ FT—881 BREATHER FABRIC

Placed over the release fabric, under the vacuum bag to provide an air passage for air to get to the port.

25FT—882 VACUUM BAG FILM

Apply sealant continuously around the outside of the release fabric area to seal the vacuum bag over the layup.

25 FT—883 VACUUM BAG SEALANT

Apply sealant continuously around the outside of the release fabric area to seal the vacuum bag over the layup.

002-150 VACUUM BAGGING TECHNIQUES

A 52-page manual that describes the basic principles and practical application of vacuum bagging for repair and laminate construction.