300 Mini Pumps

300 Mini Pumps are designed for convenient and accurate metering of Group A, B, and C sizes of the W...

303 Positive Displacement Pump

This positive displacement pump delivers 2.3 fl oz of resin and hardener per full stroke of the disp...

305 High-Capacity Pump

This pump delivers 2.0 fl oz of resin and hardener per full stroke of the dispensing lever.

306-23 Metering Pump

For metering larger quantities of 105 Resin and 207 Special Clear or 209 Extra Slow (3:1 ratio) Ha...

306-25 Metering Pump

For metering larger quantities of 105 Resin and 205 Fast or 206 Slow (5:1 ratio) Hardeners.

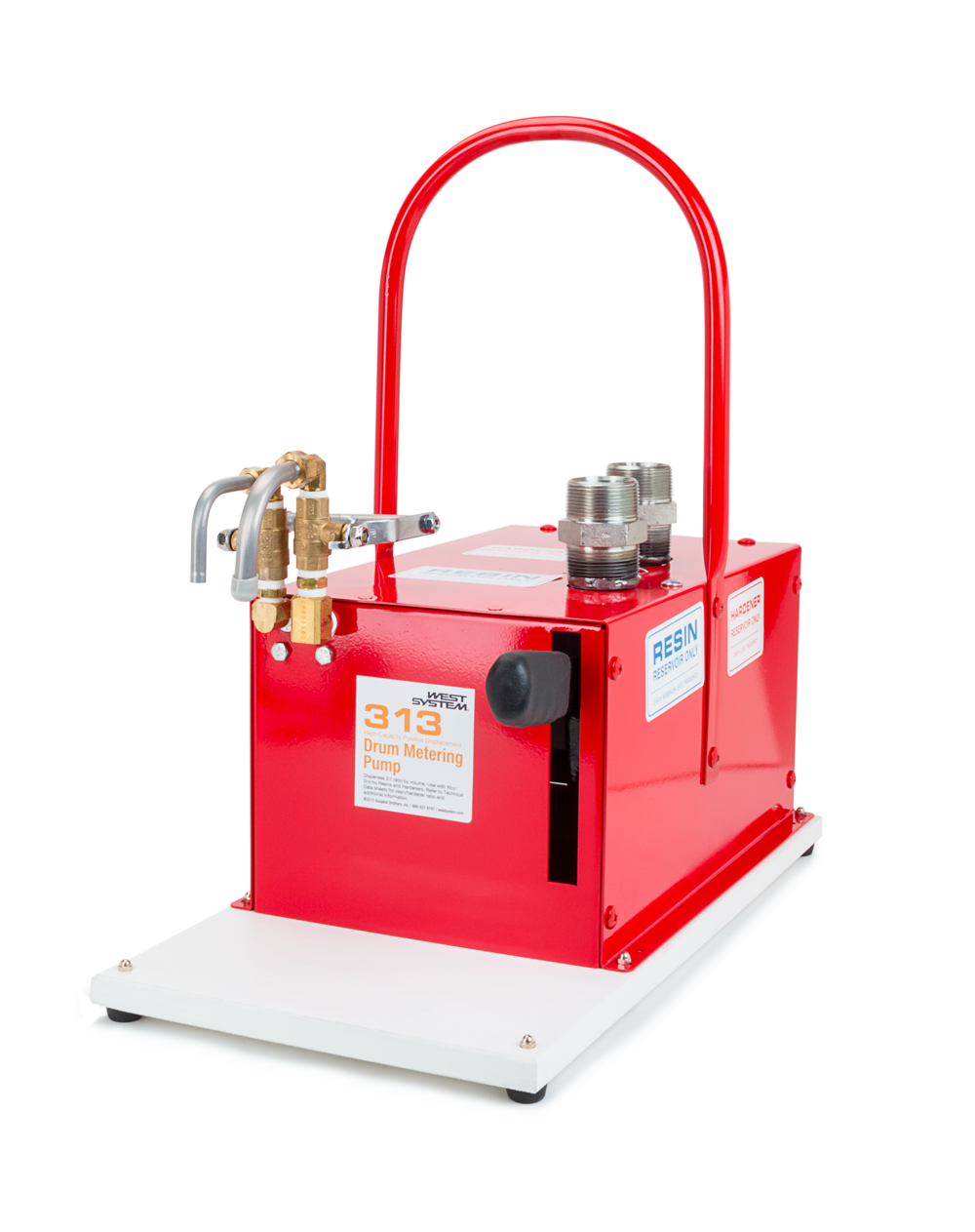

313 High-Capacity Pump

This pump delivers 2.3 fl oz of resin and hardener per full stroke of the dispensing lever.

315 High-Capacity Pump

This pump delivers 2.0 fl oz of resin and hardener per full stroke of the dispensing lever.

Rebuild Kit For All 306 Pumps

An epoxy pump rebuild kit for all 306 resin and hardener dispensing pumps.